NEW TECHNOLOGY IN DEVELOPMENT

CONVE CORP develops the first Calcium Hypochlorite Process

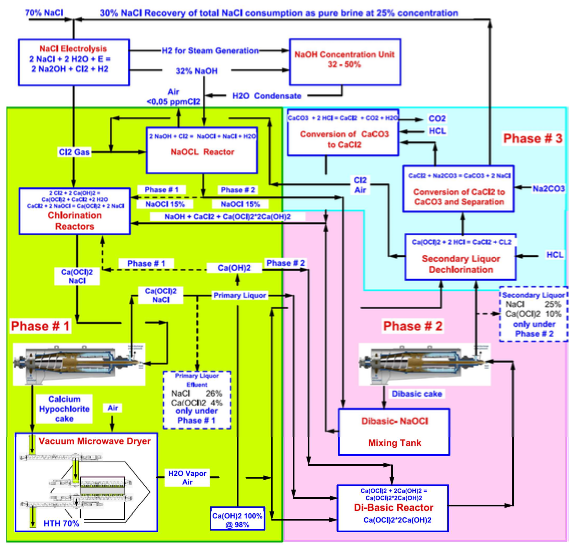

CONVE CORP offers a revolutionary new concept in the design and construction of a calcium hypochlorite plant which is completely effluent free and recovers simultaneously 30% NaCl as concentrated purified brine consumed in the electrolysis process unit, which generates all the Cl2 gas and NaOH needed, and so also 50% of the 32% NaOH produced can so be concentrated to 50% using H2 for steam production, contributing such a way to a much lower operating cost, and consequently to a much higher performance of the rate of return of the investment when compared by investing in a similar Calcium Hypochlorite plant built by any other so far known process, or in a sodium hypochlorite plant with an equivalent active chlorine output capacity.

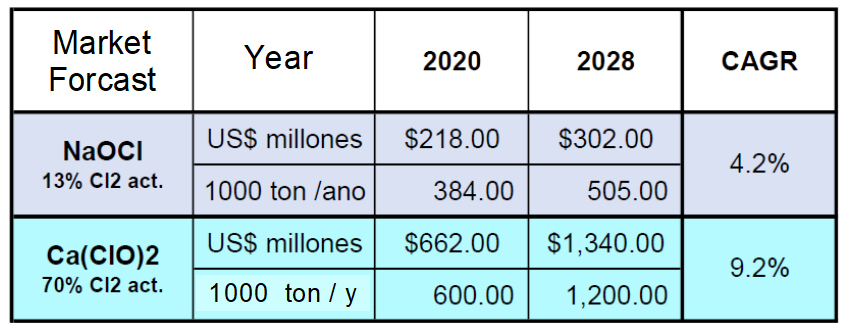

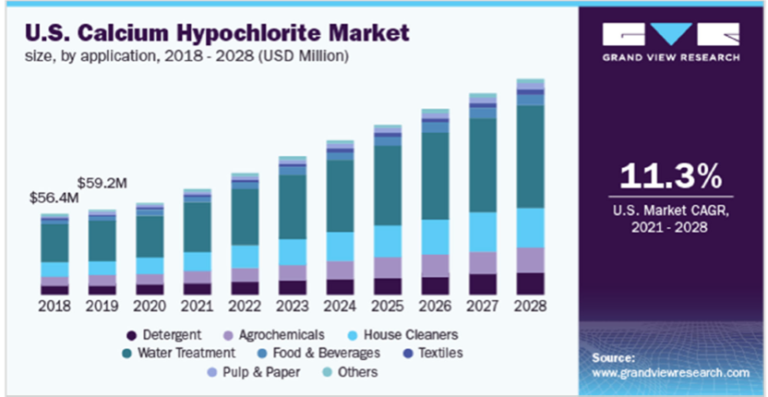

The interest of the investors generated by those big process advantages, is further boosted by the fact of the increased Calcium Hypochlorite Market Growth & Trends.

The global calcium hypochlorite market size is expected to reach USD 1.34 billion by 2028, as the market is estimated to register a growth CAGR of 11.2% during the forecast years, mainly due to the increasing demand for calcium hypochlorite from different end-user applications including household cleaners, water treatment, and agriculture, as it is used also as a filtering agent, a retention agent, a drying agent, and an oil chemical assistan

- Free of Effluents

- Recovering 30% of the salt consumed by the Cl2 generating Electrolysis

- Vaccum Microwave Drying Process